In sterile processing, accurate labeling is just as critical as tracking. While a sterilization tracking system ensures proper documentation of instruments and trays, SteriDate enhances the process by automating and standardizing labeling. When paired together, these solutions create a seamless workflow that boosts compliance, efficiency, and patient safety.

Why Labeling Matters in Sterilization Tracking

Every step in the sterilization process requires precise record-keeping. Whether it's monitoring sterilization cycles, documenting load details, or ensuring instruments are used before expiration, accurate labeling prevents errors and streamlines workflows.

Handwritten labels or outdated methods can lead to:

- Inconsistent expiration dates due to miscalculations

- Unclear recall information in case of an audit or incident

- Time-consuming labeling that slows down processing

- Regulatory compliance risks due to illegible or missing information

By integrating SteriDate with your sterilization tracking system, you eliminate these risks while optimizing efficiency.

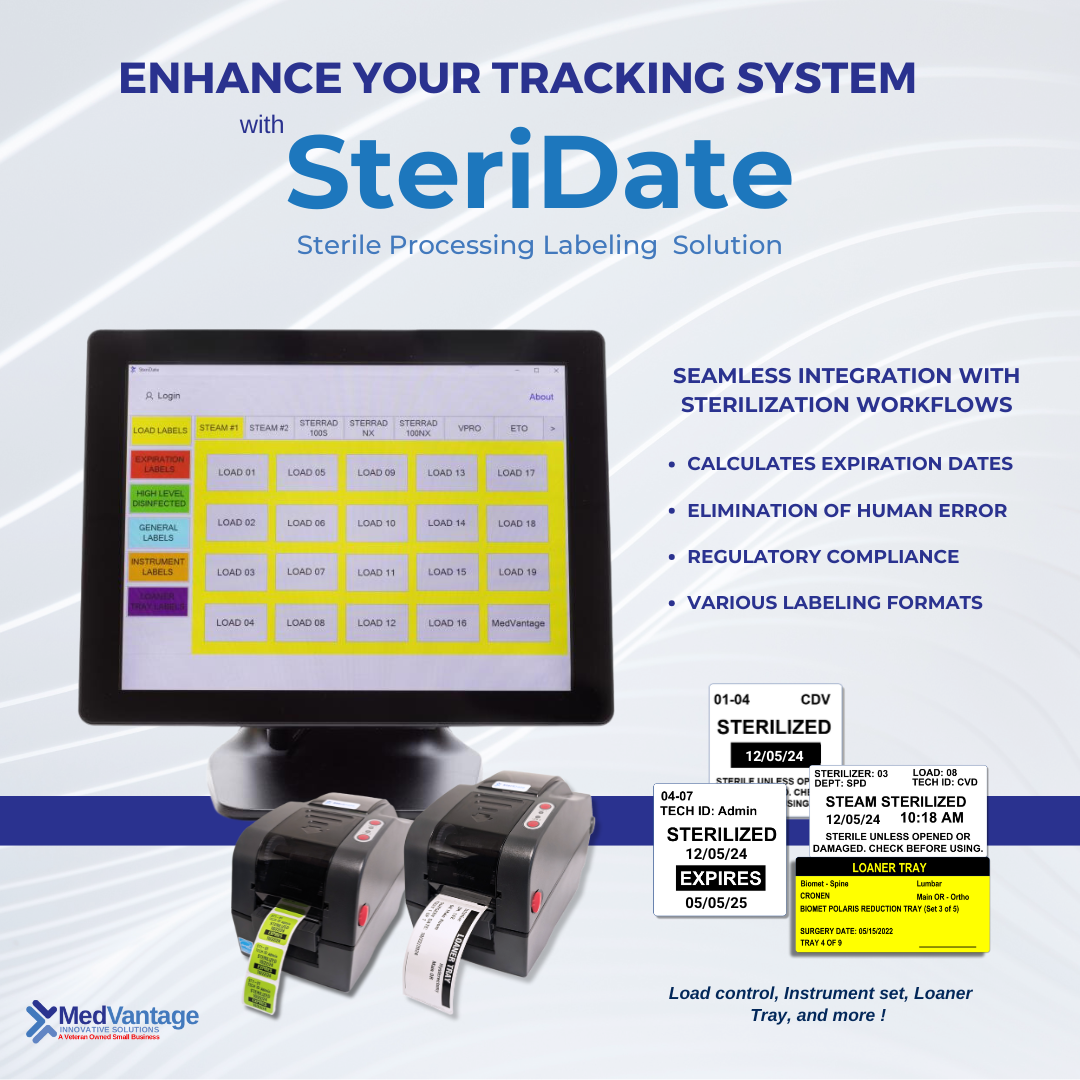

How SteriDate Enhances Your Tracking System

1. Automated Expiration Date Calculation

SteriDate removes the guesswork from expiration dates. It automatically calculates the correct expiration based on facility-specific rules, ensuring consistency across all labeled trays and instruments.

2. Standardized Label Formats

Different facilities have unique requirements for sterilization labels. SteriDate offers customizable label formats, including:

- Load control lables

- Instrument set labels

- Loaner tray labels

- Barcode-enabled tracking labels

This ensures that every item is

labeled correctly and

scannable for tracking, making audits and recalls faster and more reliable.

3. Seamless Integration with Sterilization Workflows

Whether you use a digital sterilization tracking system or a mix of manual and automated processes, SteriDate fits into your existing workflow. It provides a

touchscreen kiosk or

PC software version that works with up to two printers for on-demand label printing.

4. Elimination of Human Error

Manually writing expiration dates or tracking information increases the risk of mistakes. SteriDate ensures all

critical data is correctly entered and printed, reducing mislabeling and improving compliance with

The Joint Commission and

CDC sterilization guidelines.

5. Time Savings for Sterile Processing Teams

SteriDate automates labeling, cutting down the time needed to label trays, instruments, and loaner kits. With a simple scan and print process, teams spend less time on labeling and more time ensuring sterilization quality.

The Bottom Line

SteriDate is not just a label printer, it’s an essential

automation tool that enhances your sterilization tracking system. By ensuring accurate, standardized, and scannable labels, it strengthens your compliance efforts, reduces errors, and

creates a more efficient sterile processing workflow.

Want to see how SteriDate can improve your sterilization labeling process?

Contact us today to learn more!